So the PLA Z rod/motor couplers didn't work quite right. The PLA is a bit brittle and as I tightened the screws, I heard a bunch of cracking. It seemed to hold for a bit, but then later the couplers just slid off of the Z motor shafts. You can see the cracking in the couplers in the following pics.

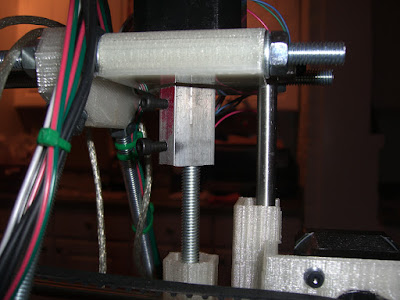

I milled out new couplers from some aluminium stock I had on hand. I drilled through at 5mm and then drilled half way through at 8mm. Then I cross drilled some 3mm holes for set screws and tapped them for m4 threads. You can see the couplers on the machine in the following pics

And I've gotten a method for hot bed mount done. I'm using plywood and have the heat bed attached to one sheet and have made it so I can detach the heat bed easily if I need to. The attachment method allows for easy adjustment to level the bed to the nozzle. You can see it in the following pics.

I still need to find connectors with sufficient ratings to connect the bed to the electronics. Also need to decide on how to attach to the electronics. And then I need to attach the endstops so it can auto home and stop the +Z motion before the belts hit the frame. I hope to have things done and printing any day now.

Hi LJ,

ReplyDeleteWith that specific hot plate, was it recommended it be mounted in that raised fashion, as against flat on the print platform? Where you concerned it would scorch the board?

Does it seem rigid enough when raised like that or is there any flex in the middle now? I'm considering this type of hot plate and would be interested in your feedback.

Tks,

No.6